In the realm of army manufacturing, precision, and durability are of utmost importance. Long bushings play a crucial role in ensuring the smooth functioning of military equipment. This post delves into the significance of these bushings in army manufacturing, shedding light on their various applications and the benefits they bring to the table.

The Versatility of Long Bushings

Long bushings, also known as sleeve bearings, are cylindrical components designed to reduce friction between two moving parts. These bushings are commonly used in army manufacturing due to their versatility and ability to withstand heavy loads and harsh conditions. Let’s explore their various applications in military equipment.

- Armored Vehicle Suspension Systems

The suspension system of armored vehicles is exposed to immense stress during off-road operations. Long bushing serve as a vital component in the suspension system, ensuring smooth movement of the vehicle’s wheels and tracks. Their self-lubricating properties minimize wear and tear, contributing to extended service life and enhanced maneuverability.

- Artillery Gun Mounts

In artillery guns, these bushings provide the necessary support and stability for gun mounts. These bushings allow the gun to be elevated or depressed smoothly while maintaining alignment with precision. The reliability of long bushing is crucial to achieving accurate targeting and firing during military operations.

- Aircraft Landing Gear Assemblies

Aircraft landing gear assemblies are subject to extreme forces during takeoffs and landings. These bushings in these assemblies help distribute the load and ensure smooth retraction and extension of the landing gear. The wear resistance and low maintenance requirements of these bushings make them essential components in aircraft manufacturing.

- Weapon Systems and Optics

Weapon systems and optics in military equipment require precise alignment and stability. These bushings aid in achieving the necessary alignment for scopes, sights, and weapon components. They contribute to the accuracy and reliability of firearms and other weapon systems used by the military.

- Tank Turrets and Gun Barrels

In tanks, long bushings are integral to the movement and rotation of turrets and gun barrels. These components allow the turret to swivel effortlessly, enabling the tank to engage targets effectively in various directions. Long bushings play a significant role in the agility and responsiveness of tanks on the battlefield.

The Importance of High-Quality Long Bushings

The performance and safety of military equipment depend on the quality of its components. These bushings are no exception. Using high-quality, precision-engineered bushings offers several advantages for army manufacturing.

- Increased Equipment Reliability

Reliable equipment is essential for successful military operations. High-quality bushings help reduce downtime and maintenance requirements, ensuring that military machinery remains operational for extended periods without compromising performance.

- Enhanced Equipment Longevity

Long bushings with superior wear resistance contribute to the longevity of military equipment. The ability to withstand harsh conditions and heavy loads without significant wear ensures that the equipment can endure rigorous use over its service life.

- Improved Performance

Military equipment performs better overall because of the smooth operation made possible by high-quality bushings. From improved maneuverability in armored vehicles to precise targeting in weapon systems, reliable bushings positively impact military capabilities.

- Minimized Maintenance Costs

Choosing durable bushings can result in cost savings on maintenance and replacement. Reduced maintenance requirements and longer service intervals translate to lower overall operational costs for the military.

FAQs

Q: Can long bushings be replaced easily in the field?

A: Yes, long bushings can be replaced in the field with the right tools and expertise. However, regular maintenance and inspections are crucial to identifying potential issues beforehand.

Q: Are long bushings susceptible to corrosion?

A: High-quality bushings are typically made from materials with excellent corrosion resistance, making them suitable for use in harsh environments.

Q: What is the expected service life of long bushings?

A: The service life of bushings depends on factors such as application, load, and maintenance practices. Quality bushings can last for thousands of operational hours.

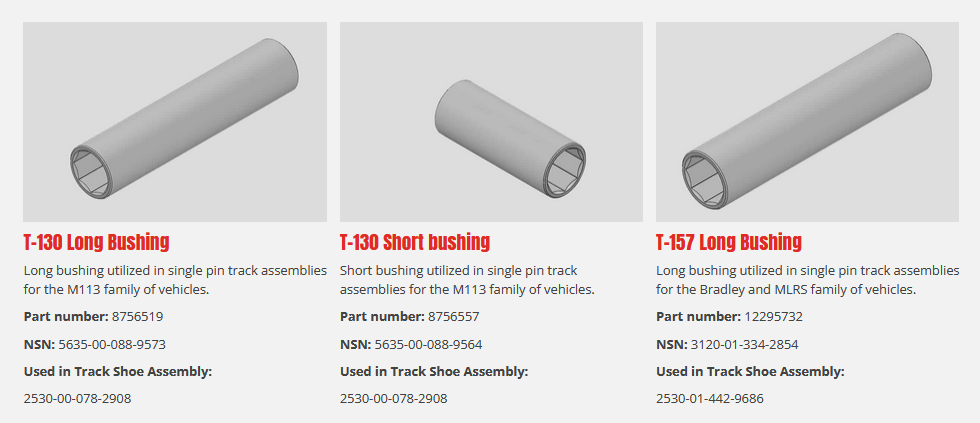

Q: Are there specialized long bushings for specific military equipment?

A: Yes, bushings are often designed to meet the specific requirements of different military equipment, ensuring optimal performance and reliability.

Q: Can long bushings withstand extreme temperatures?

A: Long bushings made from suitable materials can withstand a wide range of temperatures, making them suitable for various military applications.

Q: How often should long bushings be inspected for wear?

A: Regular inspections should be conducted as part of routine maintenance to identify any signs of wear or damage and address them promptly.

Conclusion

Long bushings play a critical role in enhancing military equipment’s efficiency, reliability, and performance. From armored vehicles to aircraft and weapon systems, these versatile components contribute to the success of military operations. The use of high-quality, precision-engineered these bushings ensures that the army’s machinery remains at its peak performance, with minimized downtime and maintenance costs. In army manufacturing, investing in top-notch bushings proves to be a strategic decision that positively impacts the readiness and effectiveness of military forces.